Factors affecting the display effect of LED screen and solutions

Are you worried that the LED screen cannot achieve the expected display effect? In the face of the display failure of the LED screen, can’t solve the problem and cause the loss of business effect and income? Do you want to keep the LED screen in good working condition to reduce the occurrence of failures? Today, we will analyze the factors affecting the display effect of the LED screen and the corresponding solutions at the technical level for you.

As a company specializing in LED screen design, manufacture and installation for more than 20 years, Galaxyav has strong technical reserves and rich field experience in the field of LED screen. We have many successful cases in LED screen projects around the world. In the field of flexible LED screen and dome LED screen, we have been leading the development trend of the industry.

Factors affecting the display effect of LED screen

1. The gap between the LED display panels is uneven

The installation gap of the LED screen panel mainly comes from two aspects. The first one is produced during the design and processing of the LED screen panel. This gap is repeatable, the phenomenon is obvious, it is easy to locate, and the uniformity can be completely solved by post-compensation.

The second is due to the gaps caused by the different installation strength and installation methods of workers during the installation of the LED screen module. This kind of LED screen panel has irregular gaps, and the phenomenon is not obvious. It will not only produce bright gaps, but also dark gaps, or there will be inconsistent brightness and darkness between modules with the same gap.

When the pixel pitch is less than 2mm, the display screen spliced by plastic kits, PCB boards, screw fasteners, etc. cannot meet the accuracy requirements after installation, so the box body is not flat, the modules at the joints are very different, and the display When the screen undergoes vibration during transportation or thermal expansion and contraction in the four seasons of spring, summer, autumn and winter, the box will deform.

As the use time of the LED screen becomes longer, the deformation of the LED screen box will become more and more, and the gap between the LED screen panels will become larger and larger. The same row of LED lamp beads are not in a straight line, these changes will cause bright lines or dark lines on the entire screen, resulting in uneven brightness and chromaticity of the LED SCREEN. Under the premise of satisfying a certain assembly accuracy, these gaps can be corrected point by point. Software improvements and fixes.

2. There are differences in the luminous performance of LED screen lamp beads between different batches

There are a lot of LED lamp beads on an ordinary LED screen, especially some LED screens with small spacing. The lamp beads installed on an LED display panel of the same area are several times that of an ordinary LED display panel. When encountering some large or giant size LED screen projects, the overall number of LED screen lamp beads is very amazing.

Since different batches of LED screen lamp beads have certain functional differences during production, if different batches of LED screen lamp beads are not used in combination, it is very likely that the partial screen of the LED screen will appear biased. bright or partially dark. Under normal circumstances, if there is a 2% difference in brightness or a 2nm difference in chromaticity between two adjacent LED display panels, the audience will feel a significant difference in the content of the picture.

In addition, in the long-term use process, we will continue to repair the failure of the LED screen, including the replacement of the LED screen panel. Since the new LED screen panel module does not match the old one, this will lead to obvious differences between different modules of the LED screen resulting in a module-level mosaic phenomenon. As the service life increases and the number of replacements increases, this problem will become more and more obvious, eventually resulting in a serious display screen phenomenon.

In response to this problem, many LED screen manufacturers adopt the method of mixing LED lamp beads to eliminate the differences in brightness and chromaticity between different batches of LED screens. It can be achieved that even if the brightness difference between LEDs reaches 10% and the chromaticity difference reaches 5nm, it is not easy to detect, but the problem is that this method cannot completely improve the problem of the LED screen. We suggest to use point-by-point correction after mixing the lamp beads of the LED screen to further improve the uniformity of brightness and chromaticity of each light-emitting pixel point.

3. There are differences in brightness and chromaticity between LED screens

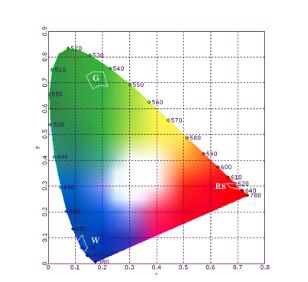

The color of the light that the lamp beads on the LED screen panel can emit is determined by its wavelength. From Figure 1, we can know that the wavelength parameters of the same color are different. The wavelength range of red is 620-640nm; there are two batches of green, The wavelength ranges are 518-525nm and 525-533nm respectively; the blue wavelength range is 465-470nm. Without correction, the difference between blue wavelengths should be less than 5nm, green wavelengths less than 10nm, red wavelengths less than 8nm, but According to the existing technical means, even if the binning process is adopted, the wavelength difference is 5nm-15nm, which cannot meet the required requirements.

4. There are differences in brightness and chromaticity between LED screens

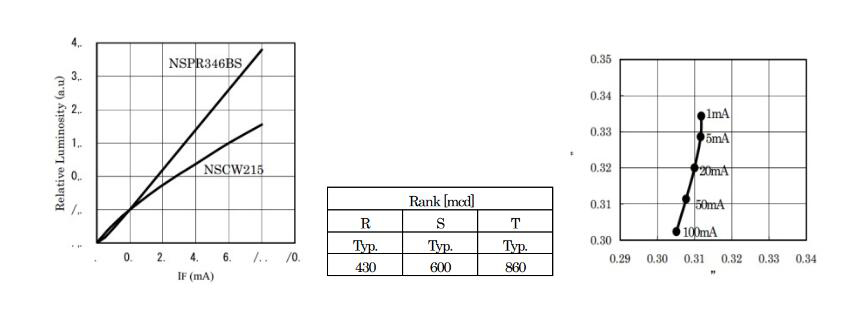

Limited by the design and manufacturing process level of the LED screen, the current on the same constant current driver chip is not the same, the current difference between the leads is 4%-6%, the current difference between the chips reaches 12%-15%, and the driving current The difference makes the light intensity and color tone of the LEDs different. The size of the current directly affects the brightness of the LED screen. The brightness of the LED screen is high when the current is large, and the brightness is low when the current is small. There are thousands of lamp beads in the entire display screen, and this difference causes the light color height of the entire screen to be uneven. If the working current exceeds the working current for a long time, the service life of the lamp beads of the LED screen will drop sharply.

5. The influence of dust in the use environment of LED screen

The use environment of the LED screen greatly affects its service life. Especially the large outdoor LED SCREEN has been exposed to the outdoors for a long time and experienced wind and sun. Over time, the surface of the LED lamp beads will be covered with dust. Over time, the dust will accumulate and thicken and the color of the lampshade will also age and turn yellow, which will have a serious impact on the display effect.

Whether the brightness or chromaticity of the LED screen decreases, it gives the impression that the screen is not clean, that is, the screen is dirty. When the air humidity is high, the dust will also absorb water molecules, corrode electronic circuits, and cause short-circuit failure of the LED screen panel.

In addition, the static electricity of the LED screen will also attract dust, and the deposited dust will affect the heat dissipation of the electronic components in the LED screen. The temperature rise of these components will accelerate the aging of the LED screen, resulting in virtual welding between solder joints, which may further lead to short circuits and fires.

6. Circuit and module design defects of LED screen

The drive circuit and module design of the LED screen will affect its service life. Since the transmission distance of the output current of the driver is too long on the PCB board, the voltage drop of the transmission path will be too large, which will reduce the normal operating voltage of the LED screen and reduce its brightness.

We often find that the brightness around the display module is lower than in the middle, which is why. Another point is that because the display area is large and consumes more power, it is powered by many separate switching power supplies, and the voltage difference between the switching power supplies will also cause a difference in brightness.

In addition, the neatness of the module kit is not good, the depth of the potting glue on the surface of the lamp board is inconsistent, and the manufacturer’s assembly process is not good, which will cause the mask to be uneven. Compared with the tube at the edge of the module, more parts of the mask are exposed ( or less), resulting in a brightness difference that slowly dims (or brightens) from the center to the edges.

7. The display angle of the LED screen is inconsistent

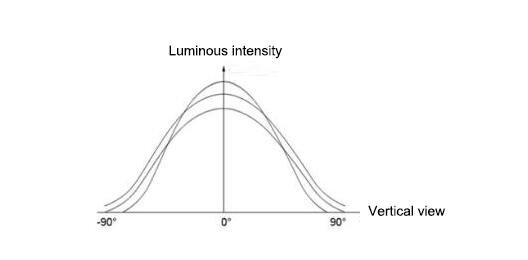

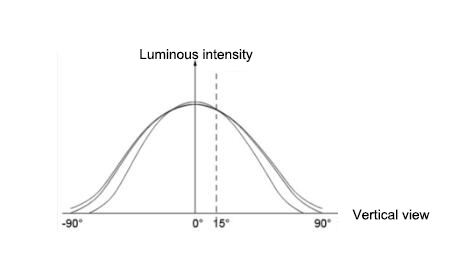

The light-emitting characteristics of the lamp beads on the LED screen determine that its display intensity along the optical axis is the highest, and the light intensity gradually decreases along the light-emitting surface. Highest. When it deviates from the normal direction, the brightness will decrease to different degrees, and the brightness of LEDs of different colors will also be different when viewed from the same angle, as shown in Figure 3-Figure 4.

In addition, factors such as the working environment and antistatic properties of the LED screen will also affect the quality and life of the LED display. For example, the influence of humidity and temperature will cause the working performance of LED and IC to change with temperature and humidity. In addition, because LEDscreen is a semiconductor component, it is sensitive to static electricity, which can easily lead to static electricity failure. Antistatic ability is also very important for life.

In addition, in the production process, due to the mismatch between the epoxy resin and the curing agent or the baking time of the outer sealant is too long, the LED lamp beads will turn yellow, and the lens of the LED made of silicone will also change its chemical properties over time. There is a change, which affects the angularity of the LED brightness, and the brightness decreases, resulting in uneven display

Want to know more about the Audio Visual Solutions?