What is the front maintenance LED screen ?

Table of Contents

According to the maintenance method, LED display screens are usually divided into two types: front-end maintenance and back-end maintenance. Back-end maintenance is the most common LED display repair method, which is usually applied to the troubleshooting and processing of large outdoor LED displays. Front-end maintenance is usually applied to indoor LED displays. Front-end maintenance has more advantages than back-end maintenance, and it is gradually replacing back-end maintenance as the main method of LED display fault repair.

What is the front maintenance LED screen?

The Front Maintenance LED Screen (FMLS) is an engineered solution that allows you to see, analyze and adjust your content remotely. It enables efficient performance tracking and makes it possible to have full control over your digital signage network. It is easy to install, requires no maintenance, and has a low energy consumption.

Advantages Of Front Maintenance LED Display

There are several advantages to using a front maintenance LED display:

Easy to maintain: Front maintenance LED displays are easy to maintain because the LED modules can be accessed from the front of the display, rather than having to disassemble the display or access it from the back. This makes it much easier to replace faulty modules or perform other maintenance tasks.

Better visual quality: Front maintenance LED displays often have a higher visual quality because the LED modules are not obscured by the structural components of the display. This can result in a brighter, clearer image.

Greater design flexibility: Front maintenance LED displays offer greater design flexibility because they do not require a large gap between the display and the wall to allow for maintenance access. This means that the display can be mounted closer to the wall, creating a more seamless installation.

Easier installation: Front maintenance LED displays are easier to install because the LED modules can be accessed and replaced from the front of the display. This reduces the time and effort required to install the display.

Longer lifespan: Front maintenance LED displays often have a longer lifespan because the LED modules can be easily replaced when they fail, rather than having to replace the entire display. This can save money in the long run and reduce the need for frequent maintenance and repairs.

Rear maintenance VS front maintenance LED billboard display

Front-end maintenance LED display: The biggest feature of front-end maintenance is to save space. For indoor or mosaic installation structures, space is extremely precious, so there will not be too much space left as a maintenance channel. Therefore, front-end maintenance can greatly reduce the overall thickness of the LED display structure, which can not only integrate well with the surrounding architectural environment, but also save space while ensuring the effect.

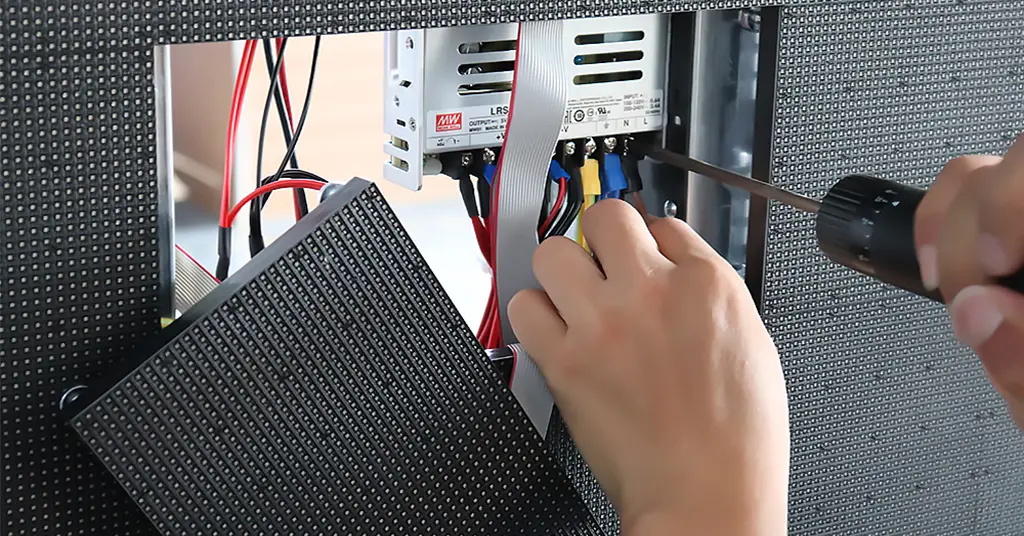

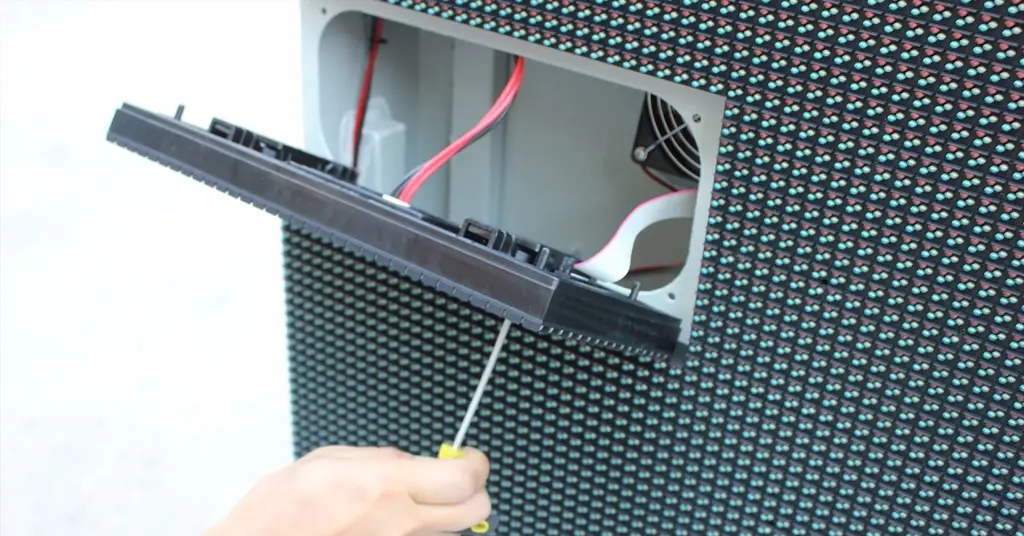

However, this structure has very high requirements on the heat dissipation function of the device. The LED module is fixed on the box by magnetic elements. When it is about to be disassembled, use the suction cup tool to suck the LED module to remove it.

The advantage of front maintenance is that the LED display box can be made lighter and thinner, and the disassembly of the LED module is more convenient and efficient.

Back-end maintenance LED display: The biggest advantage of back-end maintenance is convenient, suitable for large outdoor LED displays, roof-mounted, wall-mounted, and column-mounted, easy and efficient inspection and maintenance. For those large LED displays installed on the exterior walls of buildings, it is more convenient for maintenance personnel to enter and operate from the rear.

How to troubleshoot the front maintenance led display?

Multiple modules of the LED display are not bright or abnormal

Check whether the cables and power cables of the first abnormal module in the signal direction are in good contact. If the LED light bead of the module is not on, it means that there is no power input, so you need to use a multimeter to check whether the power supply is abnormal.

If there are patterns on the LED display, but the patterns are messy and bright, it means that the module has not received signal input. Please check that the input terminals of the first abnormal module are in tight contact. You can try to re-plug the signal cable or replace it with a new one.

A single module of the LED display does not light up

When a single lamp bead of the LED display screen does not light up, please use a multimeter to detect it. First, turn the multimeter to resistance X1, then use the black pen of the multimeter to touch the positive pole of the LED light bead, and the red pen to touch the negative pole of the LED light bead. If the LED light bead does not light up, it means that the light bead is damaged and needs to be replaced.

Select the corresponding type of screwdriver to remove the screws used to fix the mask from the front of the LED display, and replace the lamp beads after removing the mask. After replacing the lamp bead, seal it with sealant, restore the mask, and tighten the screws. If there is glue residue on the surface of the LED display, please remove the glue residue.

Others also read the following article

Want to know more about the Audio Visual Solutions?