How to calibrate LED screen point by point ?

LED transparent display screen is becoming a new favorite in the market, and its unique image and video display method have a completely different effect compared with the traditional LED screen. At present, the LED full-color display is limited by the technical level and product cost, and the price has remained high. Although the theoretical life of the LED screen is 100,000 hours, in fact, after about 5,000 to 10,000 hours of operation, the original performance will be reduced in terms of color clarity and display brightness.

The reduction in the color definition and display brightness performance of the LED screen will directly lead to a reduction in the commercial value of the LED screen. Most advertisers will choose other methods or other LED screens with better display effects to place commercial advertisements. After 15,000 to 20,000 hours, the commercial value of the LED screen is almost lost, and at the same time, it will cause a huge waste of social resources. has remained high. Although the theoretical life of the LED screen is 100,000 hours, in fact, after about 5,000 to 10,000 hours of operation, the original performance will be reduced in terms of color clarity and display brightness.

Although the transparent LED screen is a unique LED screen, its working principle and use effect curve are not particularly different. Considering its higher production cost, it is necessary to master the troubleshooting method of LED transparent display. Galaxyav has more than 20 years of professional experience as an LED screen manufacturer engaged in the design, manufacture and installation of LED screens. In this article, we will introduce the method of point-by-point correction of LED transparent display.

The point-by-point correction technology of the LED screen allows users to greatly improve the uniformity of LED SCREEN at a very low cost in a very short period of time, significantly improving the display quality of images and videos. After the point-by-point correction of the LED screen panel, the display effect of the full-color LED display can be extended, creating more commercial value for users and reducing waste of resources.

Correction technology of LED screen panel

At present, there are two mainstream screen point-by-point correction technologies in the LED screen market: on-site point-by-point correction technology and LED cabinet point-by-point correction technology. These two point-by-point correction technologies are very different in specific maintenance methods, processing objects and the display effect of the corrected LED screen.

1. On-site point-by-point correction technology

The maintenance object of this LED screen panel point-by-point correction technology is the entire installed LED screen or the LED screen that has been used for normal advertising. Due to the influence of environment, weather and technical compatibility problems in different places, the calibration cost will be higher, which is more suitable for the maintenance of large-scale LED screen projects in foreign countries or overseas.

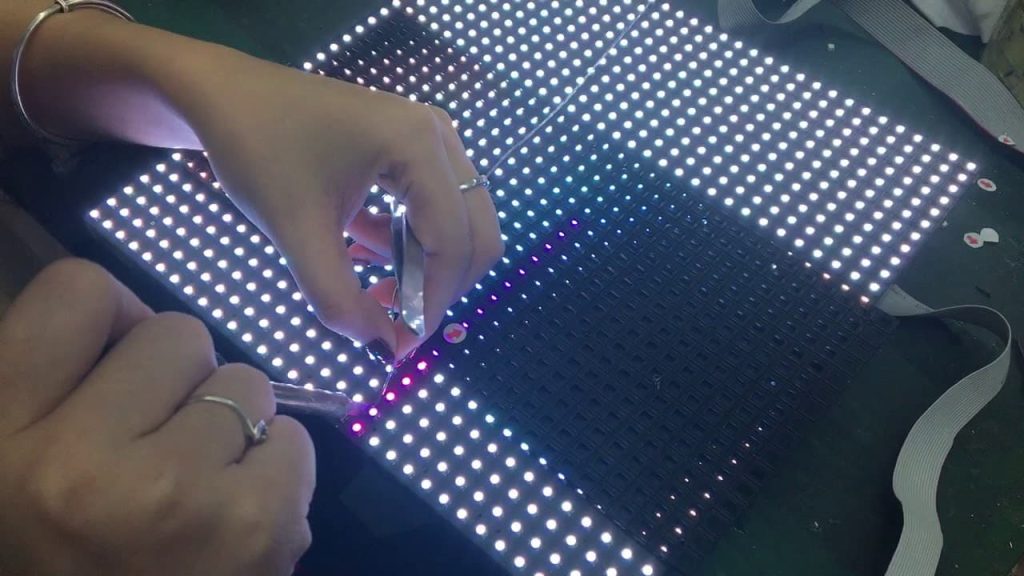

2. LED cabinet calibration point by point

The maintenance object of the point-by-point correction technology of the LED screen panel box is the LED screen that has not yet been shipped or installed. At present, in the field of transparent LED screen inspection and maintenance, the point-by-point calibration technology of the cabinet is becoming the mainstream. Compared with the point-by-point correction on the project site, the point-by-point correction technology of the cabinet has greater advantages in terms of cost saving, ease of operation and the display effect of the corrected LED screen.

Led screen display effect correction method

The cabinet calibration of the LED screen is usually arranged in the last link before leaving the factory. The main purpose is to eliminate the brightness and chromaticity difference between the LED screen cabinet and the cabinet, and improve the color uniformity of the overall LED display screen after splicing. In order to better improve the point-by-point correction effect of the LED screen, we usually use three methods to track the quality control.

Led screen display effect correction method 1

Splicing all the LED screen panel boxes to be tested, and observe the image (or solid color) on the led screen after power-on. This calibration method is the most comprehensive and has the best effect, but the disadvantage is that a large number of LED screen panel cabinets require a lot of human resources when splicing, and the operation is not very convenient.

Led screen display effect correction method 2

A part of the LED screen box is randomly selected from the LED screen panel to be tested for sampling testing. This method is a reduced version of all detection. The advantage is that the inspection cost can be greatly saved, and some LED screen panels with poor display effect can also be found. The disadvantage is that the probabilistic random sampling of test samples can easily lead to deviations in the test results.

Led screen display effect correction method 3

Use the measurement data recorded by the calibration system to simulate and evaluate the calibration effect of all LED screen cabinets. This detection method is the neutralization of the above two LED screen detection methods. It not only saves a lot of manpower and time costs, but also improves the detection accuracy of the LED screen panel to a certain extent. It has laid a solid foundation for improving the display performance of the overall LED screen.

The key point of point-by-point correction of the display effect of the LED screen

Similar to the on-site correction technology of LED screen, the point-by-point detection scheme of LED screen usually includes data acquisition, data analysis, target value setting, correction coefficient calculation and coefficient uploading and other project links, and also requires the cooperation of the control system. In order to further improve the accuracy of point-by-point correction of the LED screen box, we should focus on two technical difficulties.

1.Pixel uniformity inside the LED screen box

A. Brightness and chrominance uniformity correction

The brightness and chromaticity information of each LED lamp in the LED screen panel box is measured by measuring equipment. The measurement method involves the knowledge of photometry, chromaticity and digital image processing; after obtaining the chromaticity information one by one, according to the corresponding Correction standard, calculate the corresponding correction coefficient and send it to the receiving card of the corresponding cabinet; after the cabinet is lit, the display control system will adjust the LED current according to the correction coefficient, so that the brightness and chromaticity of all LEDs in the cabinet are consistent .

B. Brightness and Darkness Uniformity Correction

It is to adjust the fluctuating LED brightness to a consistent level. In the process of adjusting the brightness, it is necessary to appropriately reduce the maximum brightness value of most LEDs. Chromaticity correction is based on the principle of RGB color matching, and solves the problem of chromaticity deviation by changing the color coordinates of RGB three colors. For the color gamut comparison diagram before and after correction, the large triangle is the color gamut of the display screen before correction, and RGB three colors The color coordinates are discretely distributed; the small triangle is the corrected color gamut of the display screen, and the RGB three-color color coordinates are consistent.

2. Consistency of brightness and chromaticity between LED screen cabinets

The human eye can only distinguish the brightness difference of more than 4-5% between LED pixels, but can easily identify the 1% difference in brightness and chromaticity of the LED screen panel box. That is to say, the human eye has lower requirements on the consistency of the pixels inside the LED screen panel box, but higher requirements on the consistency between the LED screen panel boxes. Therefore, the consistency of brightness and chromaticity between LED screen panel cabinets is a key technology unique to cabinet calibration.

The inconsistency of brightness and chromaticity between LED screen panel cabinets is mainly reflected in two aspects:

A. There are differences in the average brightness and chromaticity between the LED screen panel cabinets. When splicing the LED screen panel cabinets, there will be obvious boundary lines, which can be achieved by adjusting the color gamut and setting the appropriate target value; necessary, a colorimeter with higher accuracy is required for auxiliary measurement.

B. The brightness and chromaticity distribution of the LED screen panel box presents a gradient distribution, which is caused by the gradient distribution phenomenon in the measurement data of the LED screen panel box. When the LED screen panel boxes are spliced together, the brightness of the splicing place will undergo a large jump, forming an obvious splicing line. This requires the correction system to be able to detect and resolve the gradient distribution of the measurement data

Want to know more about the Audio Visual Solutions?